If you are looking to build or renovate your home, you may have asked yourself “how can I limit the passage of energy (heat) from one side of my house to the other, thus reducing the amount of energy (fuel) required for heating & cooling”… maybe not those exact words, but that is precisely what I set out to do here.

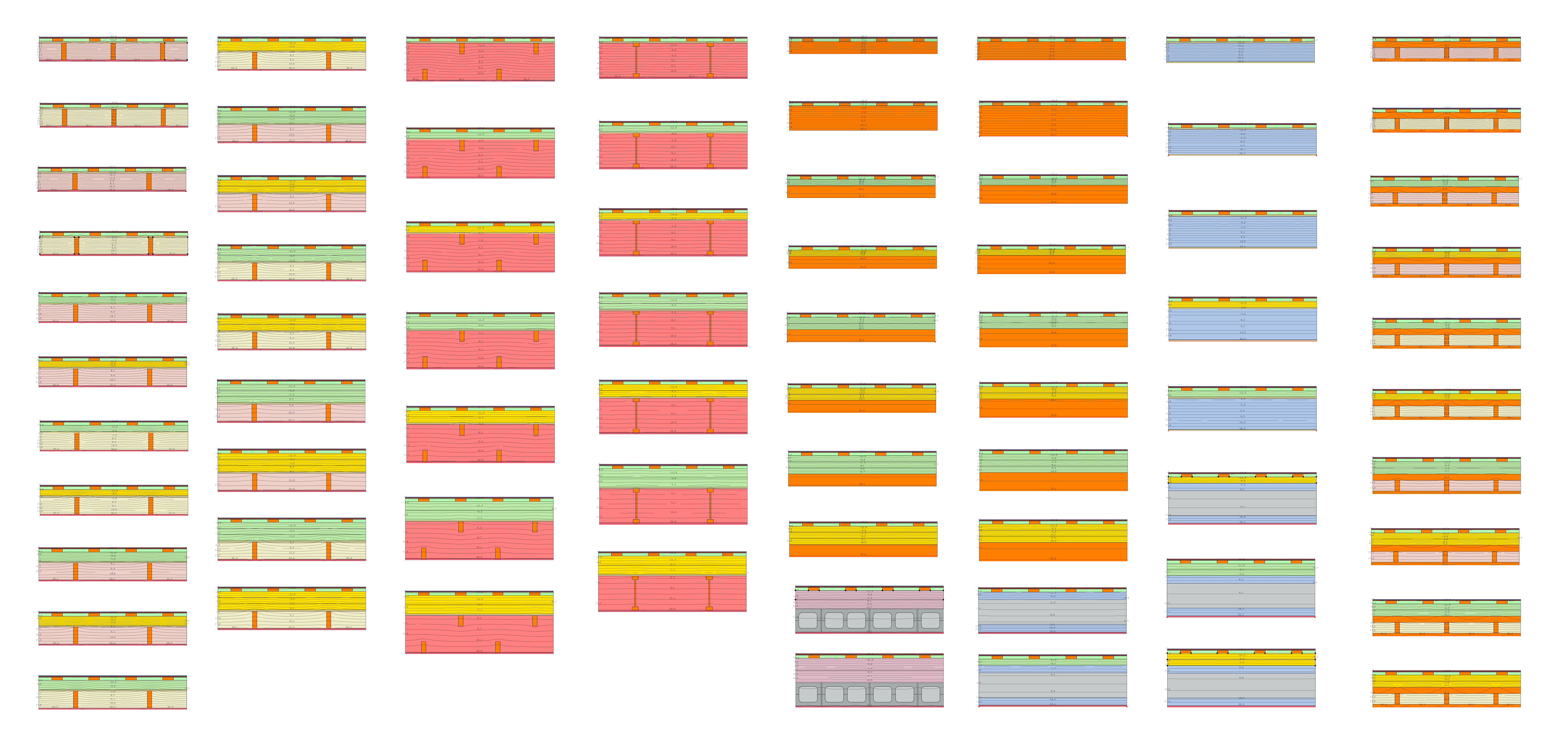

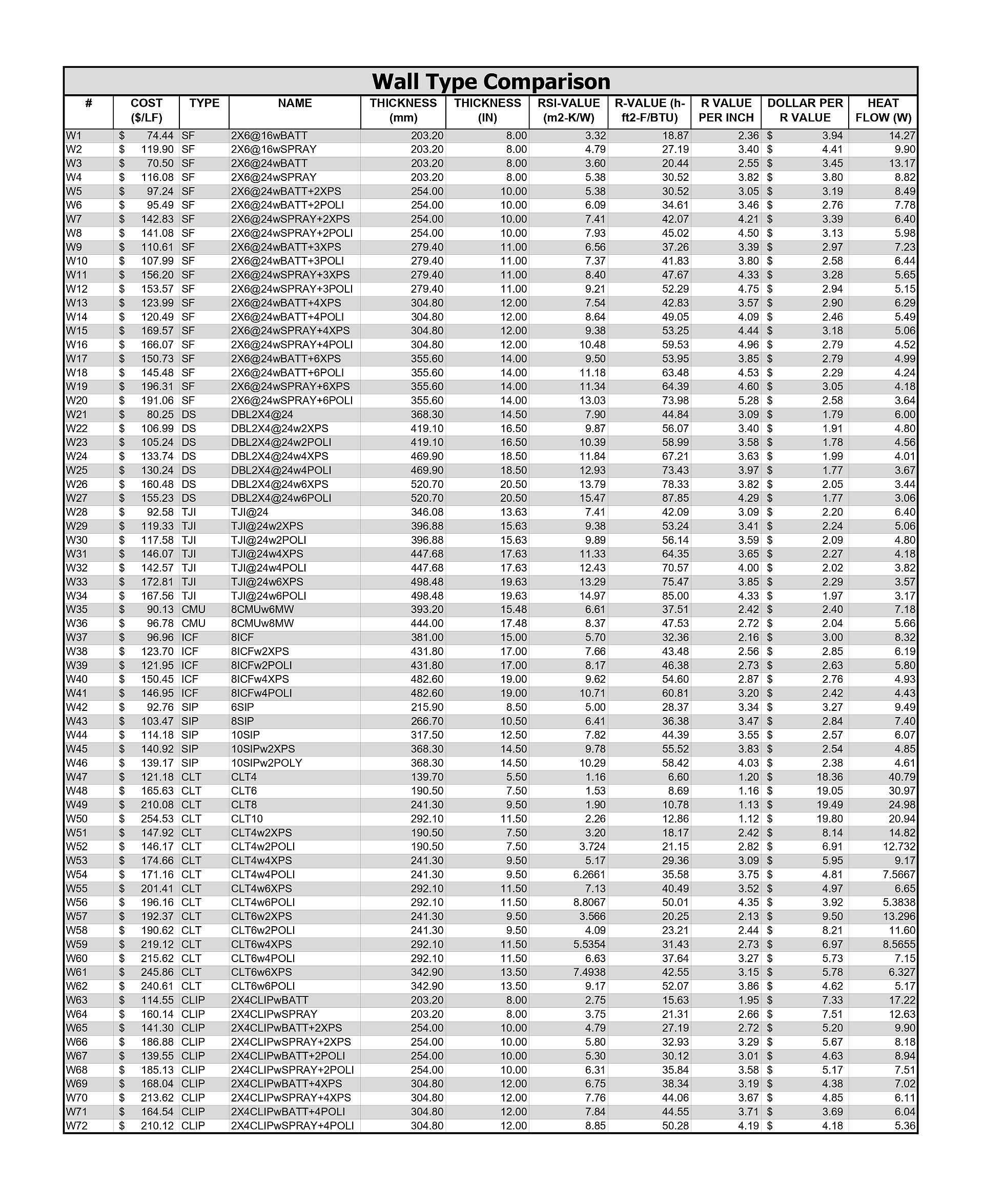

Below is a listing of 72 different wall assemblies I modeled and tested in Therm7.7 to check their clear wall R-value, then checked price data to determine their cost per linear foot. I then compared them to determine which wall type is ‘best’ given a set of different scenarios.

1. Introduction of Wall Types Tested

Most or all of the walls contain an interior finish of gypsum board (drywall), exterior plywood sheathing, a 1/2” air barrier, and wood siding. The structural layer, insulation type, and insulation amount were varied and tested against one another. The different structural layers and insulation types/amounts are summarized below.

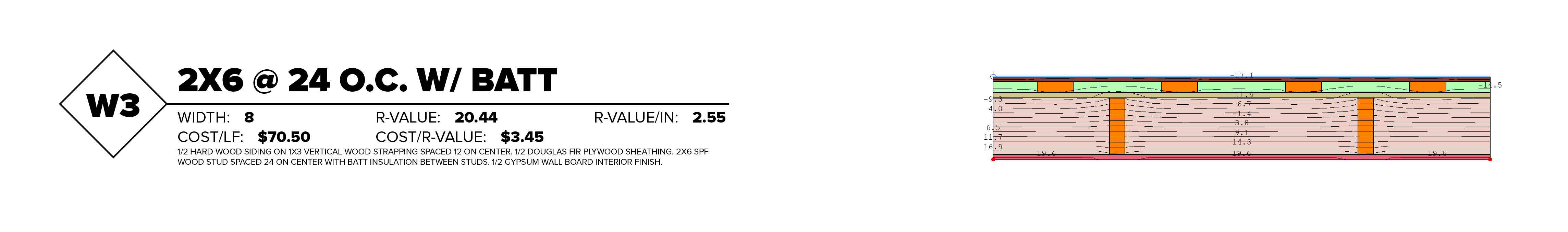

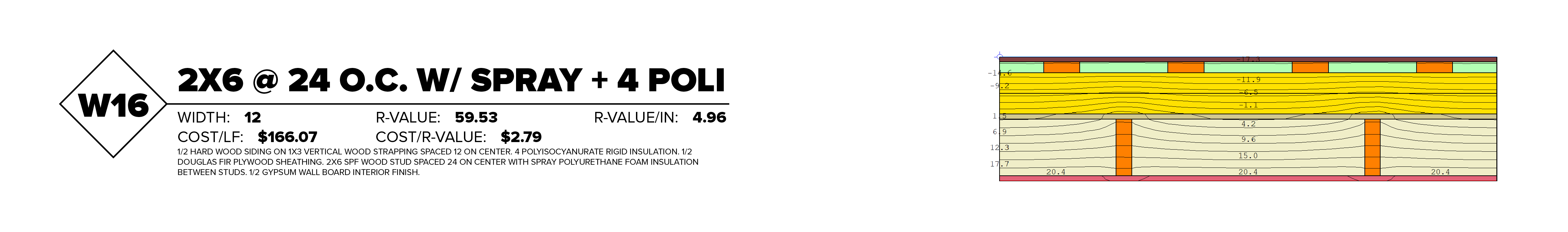

Stick Frame Walls (SF) — This is your typical wood stud wall with insulation added between studs, and with or without additional insulation added between the exterior plywood sheathing and siding.

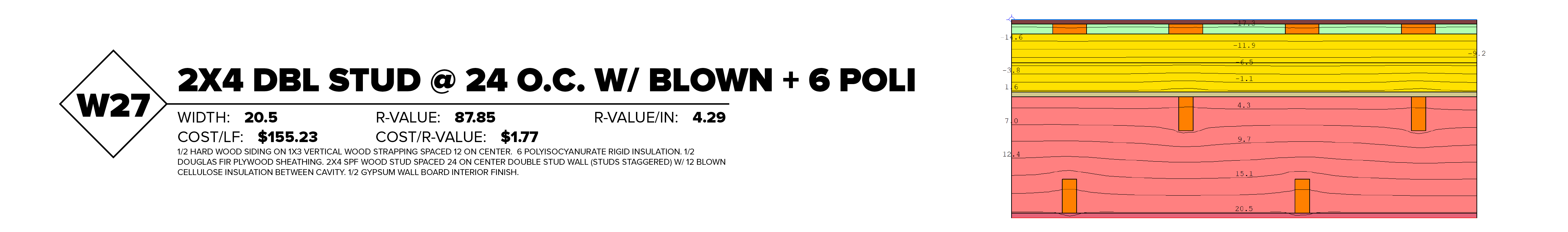

Double Stud Walls (DS) — Think of this as two wood stud walls spaced between 8-12” apart with the gap between the two filled with loose fill insulation.

I-Joist Wall (TJI) — I joists are a specially manufactured type of stud which function the same but are capable of being manufactured to greater depths than typical wood studs (being dependent on the diameter of the tree they are felled from). This in turn allows for a thicker wall cavity, and thus adding in more insulation.

Concrete Masonry Unit (CMU) — More common with commercial jobs or in basements. Concrete blocks are stacked into a wall with insulation added to either the exterior or interior surface of the wall.

Insulated Concrete Forms (ICF) — Also more common for basement applications, however have the potential for use for the entire house. Here rigid insulation acts as the formwork for concrete the be poured into. Once the concrete cures, the insulation remains in place, serving as the buildings insulation.

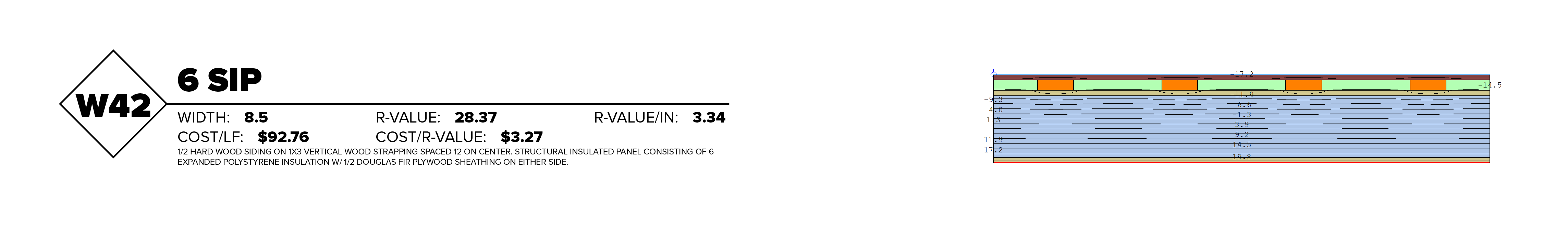

Structural Insulated Panels (SIP) — These are pre-manufactured wall panels consisting of an inner layer of rigid insulation, sandwiched between plywood sheathing on either side.

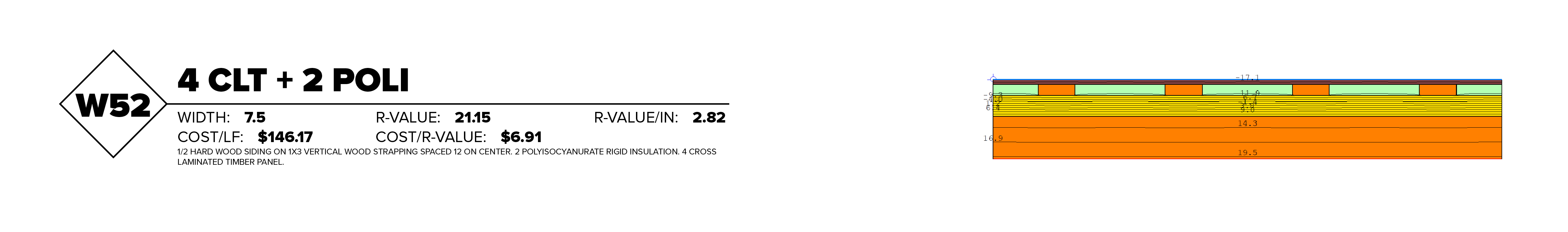

Cross Laminated Timber (CLT) — This type of wall is made up of layers of wood studs oriented perpendicularly layer by layer then glued together into a solid panel typically made between 6-10” thick by most manufacturers. Insulation is then added onto the exterior or interior side.

Cross Laminate Insulated Panels (CLIP) — These are also pre-manufactured walls, here using thinner CLT panels as interior and exterior sheathing, separated by wood studs and with a cavity filled with insulation.

For insulation I tested:

Fiberglass Batts (BATT) — The ubiquitous fluffy pink stuff seen in 99% of residential homes.

Blown-in Cellulose (BLOWN) — Typically found in attics where gravity alone holds it in place against the ceiling.

Spray Foam (SPRAY) — Becoming increasingly more popular this type of insulation starts out as a liquid and that is sprayed directly onto wall/floor/ceiling surfaces where it expands into a continuous and air tight barrier.

Expanded Polystyrene (EPS) — Essentially the same stuff used as packaging material. It is rigid, comes in sheets, and is more common below basement slabs and as the formwork for insulated concrete form walls.

Extruded Polystyrene (XPS) — Another rigid type of insulation that comes in sheets and is used most often applied to the outside surface of walls for creating a continuous layer of thermal resistance uninterrupted by structural members.

Foil Faced Polyisocyanurate (POLI) — A higher quality rigid insulation that has a reflective foil face on one side to reflect solar radiation.

Mineral Wool (MW) — This semi-rigid wool fiber insulation is more commonly used on commercial jobs because it can be left exposed to the weather for longer periods of time than other options, thus making it less susceptible to damages due to delays in the build if left exposed.

Summary of Data

Below is a summary of all the data used for the different wall types. including cost of materials, R-value, thickness of wall.

Comparrison

Which wall is best really depends on your needs. Are you trying to spend the least amount of money on heating costs every year? Or maybe your building footprint is limited so you cant afford to give up the extra square footage thicken your walls with extra insulation. Below I listed a few different scenarios and the best wall type suited to each of those conditions.

Highest R-Value

Coming in at R-87.85, the W27 provided the most thermal resistance of the walls tested. It also happened to be the thickest at over 20” thick. One way to turn this into an advantage however is to convert the window openings into a bench, banquette, or even a reading nook by setting the windows as close to the exterior surface of the wall as possible, thus creating a nearly 20” deep slab for sitting.

Highest R-Value per Dollar

In terms of bang for your buck, all of the double stud walls hit the mark, each coming in at under $2 per unit of thermal resistance (R-value). The W21 is the best option for those who care about the environment, but are building on a budget.

Highest R-Value per Inch

At R-5.28 per inch, the W20 was the most efficient wall assembly in terms of maximizing the potential of every inch given over to wall area.

Least Expensive

At $70.50 per linear foot of wall, the W3 is the cheapest wall assembly of all the ones tested which still meet the minimal standards for thermal comfort and energy performance set out in the building code.

Thinnest

When you cannot afford to give up interior square footage to thicken your walls with added insulation, the W52 was the least thick option tested. It should be noted that this wall was only a 1/2” thinner than the W3 and costs twice as much. So unless you are using CLT for some other purpose (it looks really cool?) most cases would benefit more from just using the W3.

Highest R-Value Under 12” Thick

Spray foam insulation and foil-faced polyisocyanurate insulation cost a premium because they are so efficient in terms of the thermal resistance they provide per inch. Utilizing both of these is the W16 and not surprisingly provides the highest R-value (almost R-60) in a wall just 12” thick.

Highest R-Value per Dollar Under 12” Thick

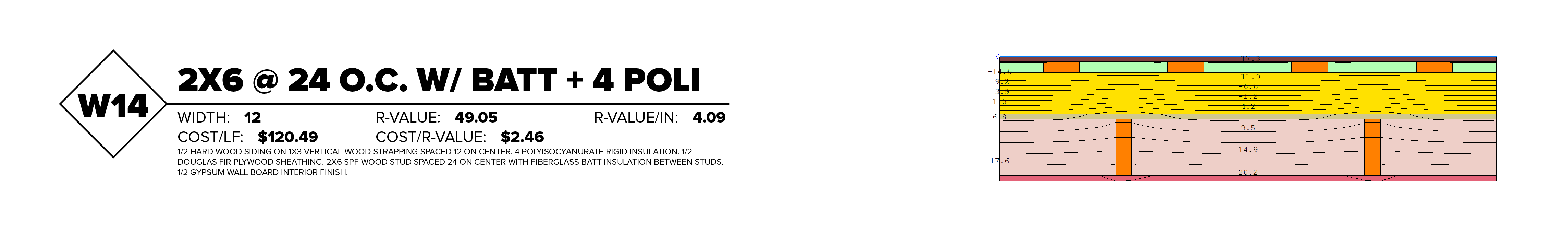

Using more conventional materials the W14 offers the highest R-value per dollar spent in a wall assembly under 12” thick. This wall type is useful for when you have limited space to give up for added insulation but cant afford premium insulation materials.

Highest R-Value Under 9” Thick

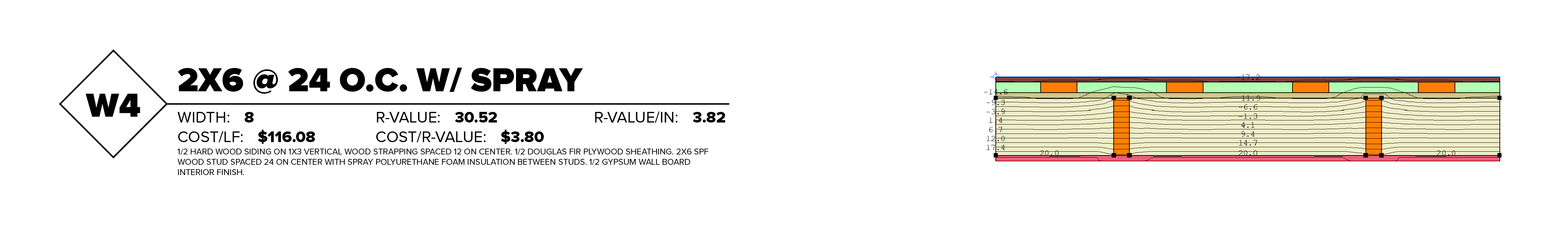

Not surprisingly the 2X6 wall with nothing but spray foam insulation was the highest R-value at R-30 in a wall assembly totaling only 9” thick.

Highest R-Value per Dollar Under 9” Thick

SIPs are probably the most efficient in terms of size, seeing as the insulation works in tandem with the exterior sheathing to act as the structural layer as well, making for an incredibly compact wall assembly. The W42 is the best option for when you are building on a budget and are very limited in space.

Conclusion

Realistically either of these wall types will work fine in 99% of build cases. But choosing which wall type works best for your project depends on the unique factors related to your build. In any case, hopefully this helps you make an informed choice of wall type for your next project.